Supply Chain, Logistics, and JIT Inventory In 2022

With the pandemic still in full effect, we have seen many supply chain disruptions and distribution backlogs. A chain reaction (pun intended) is still being felt as we head into 2022. it’s more difficult to import medical supplies, imports are backed up and exports of crops and other American made products are experiencing delays.

As a result, supply chain workers face extended hours to work through the backlog and retailers, manufacturers, and other businesses are left waiting for delayed materials, and goods. Another unpleasant side effect? Ships lingering in port areas are causing emissions to rise, creating concentrated air quality issues around these areas.

Supply Chain Trends in 2022

As we bid farewell to 2021, we officially have another year of battling supply chain disruptions behind us. What are some of the supply chain trends we will be seeing this year?

Filling the Labor Gap

Automation technology and artificial intelligence have been seen filling the labor gaps this past year. Experts predict we will continue to see this trend grow throughout 2022. Automation should not be seen as getting rid of human workers but rather a tool to fill in the gaps.

Capacity Shortage

We will continue to see a capacity shortage in 2022. Shipping volumes continue to grow with little capacity due to Covid-19. Rental prices in ships continue to grow and OTR driver shortages and labor shortages only exacerbate the issues. Companies have been seen switching to airfare to get their products moving quicker.

Supply Chain Technology

We are seeing more and more companies turning to cloud-based enterprise resource planning. This has allowed companies to be more secure and reliable when overseeing supply chain operations. Advanced technology improves efficiency and creates a more connected supply chain, eliminating potential delays and backlogs through proactive channel management.

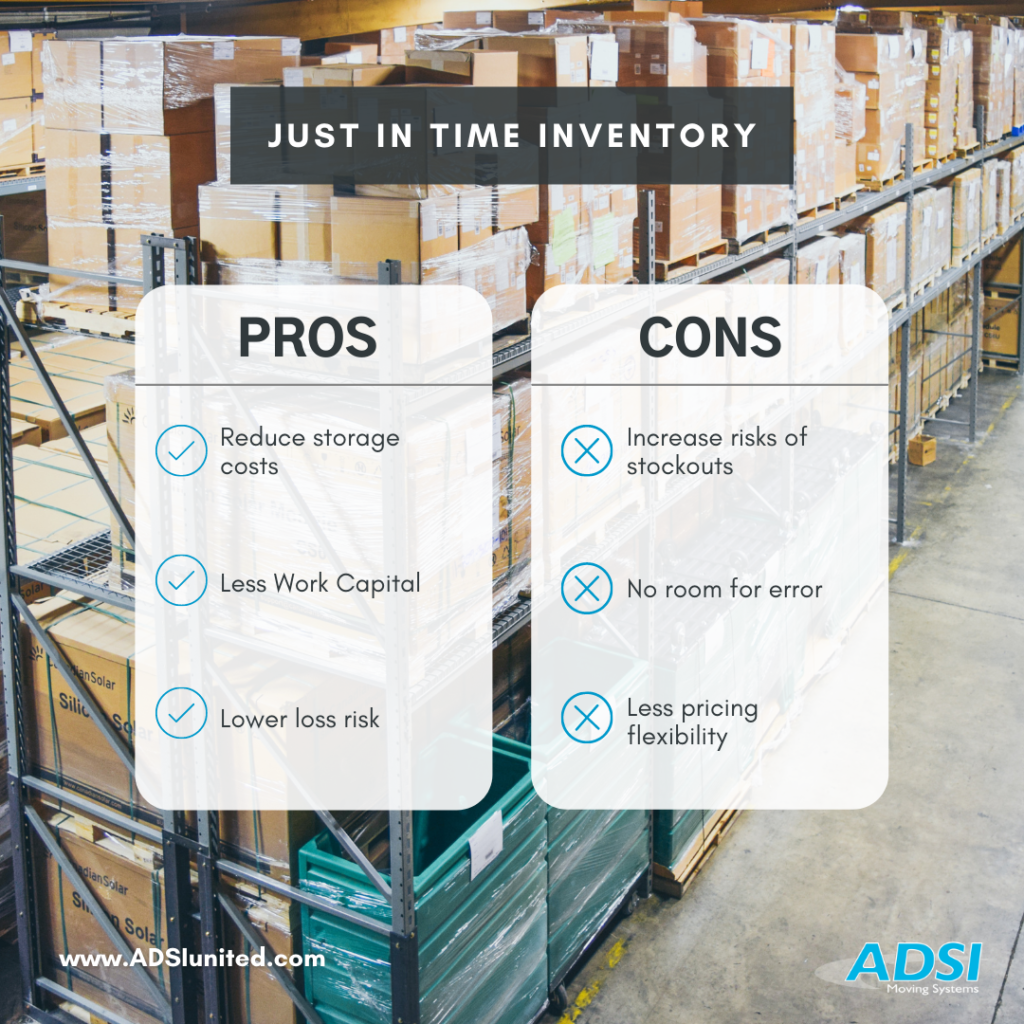

Just-In-Time Inventory

If keeping inventory costs low and maintaining a steady supply of inventory works best for your company, Just-In-Time Inventory (JIT) may be your solution. JIT allows you to keep as little inventory to avoid high storage costs and keeps your inventory fresh. JIT doesn’t work for everyone, if not executed correctly it could end up hurting your business.

Pros

When done correctly, JIT can enhance your profits and efficiency.

Reduce Storage Cost

When using the JIT system you are able to keep your storage costs low by keeping your inventory low.

Less Work Capital

By spending small portions of your earning on inventory that you know will sell rather than buying a mass amount, it leaves you room to spend that money elsewhere.

Lowers Loss Risk

Ordering smaller numbers at a time doesn’t leave you with the risk of not selling all of your product.

Cons

Increases Risks of Stockouts

Stockouts can cause your business the risk of not having enough inventory to meet your demand. Customers rely on satisfaction so if you plan on using the JIT method you will need to streamline your production processes and supply chain management.

No Room For Errors

When it comes to the JIT system there is no room for missed shipping windows or slower-than-usual production.

Less Pricing Flexibility

JIT means that you may have to lower your profit margin due to refilling your stock once you sell. This doesn’t allow you to have the option to wait for the best prices on your product.

Just-in-time inventory management doesn’t have to be a risk. Having a local, logistics-ready storage partner you can trust means that you can still order and manage backstock of supplies without increased on-site storage costs and the assurance of convenient, local access and final mile delivery options.

ADSI Logistics Storage Facility

Is your company looking for a local storage solution for backstock storage and materials/inventory storage? ADSI is the perfect storage solution for you and your business.

Whether you are relocating, opening a new space, or you need to keep a large inventory on hand, ADSI offers a logistics-ready warehouse to make shipping, receiving, cross-docking, storage, and final mile delivery solutions a breeze.

Secure and Organized

With nearly 50 years of experience, ADSI takes pride in our secure and organized logistics and distribution services. You can have peace of mind that your products, furniture, equipment, etc. are safe with us. Our barcode tracking system sorts and monitors your inventory shipments. Always know where your inventory is, what inventory we have, and when it has entered/exited our facility.

When you are ready to relocate your items, whether it’s across town, the country, or the world, our trained crew will prep and account for your inventory before it leaves our facility.

Ready to improve your logistics storage in 2022? We’re here to help, get in touch with one of our logistics experts today.